Introduction

Some time ago, I had the lucky opportunity to teach a group of highly talented people the concepts behind energy efficient computing during a 2 week summer school in the Swiss mountains. One of the objectives in this summer school was to understand the main principles behind IoT and the maker space. We did not want to stay theoretical, which is why we spent some nights on actually building interesting applications.

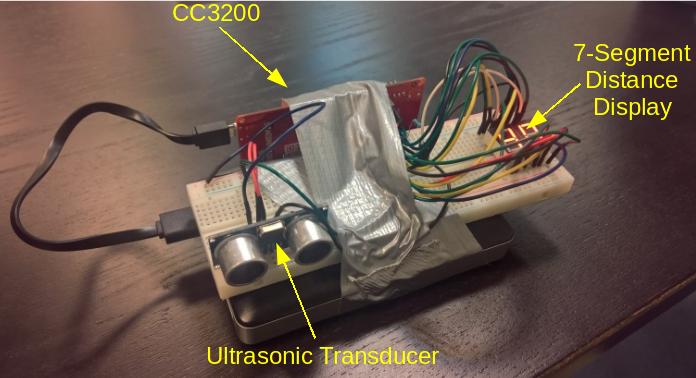

One of the simple toy projects we created was a car distance sensor. The idea was to create a small Arduino (or CC3200) compatible code base, which fits perfectly to a given wiring. The hardware setup would be quite portable as well.

The result of this article may look like (shown with the CC3200 board, Arduino looks similar):

Parts

You will need the following parts for this tutorial:

- An ultrasonic transducer,

- two seven-segment displays,

- an Arduino Nano,

- two logic-level n-channel MOSFETs, and

- two 220Ω resistors.

Let's reflect shortly on some of these parts.

Ultrasonic Transducer

The ultrasonic transducer is the main component of the setup. It works exactly the same way like the orientation system of bats. It emits ultrasound which is reflected back by an object. The time between the emission and the reception of the reflection can then be used to calculate the distance to the reflecting object.

The ultrasonic transducer provides four different pins. Two pins for the power supply, GND and VCC, a pin for triggering an ultrasound emission, and a pin which signals when the reflection has been received.

For convenience, we are not going to drive the ultrasonic transducer with hand-written code, but rather use this library.

Seven-Segment Display

There are several kinds of seven-segment displays. Their main difference is whether they provide a common cathode or anode. The seven-segment displays we are using have a common cathode, that is, all the segments share a common connection to GND. Seven-segment displays provide in addition to the common pin a dedicated pin for each segment. Which pin belongs to which segment is also type-specific. You can look up the assignment in the data-sheet of your display. The segments of a display are labelled with the letters from A to G as in the picture below.

Since the Arduino Nano does not provide enough pins to drive two seven-segment displays independently we are using two MOSFETs to switch between them with high rate. This allows us to use only one pin for each segment of both displays.

Each MOSFET provides three pins, the gate pin (G), the source pin (S), and the drain pin (D). When there is no voltage applied to the gate pin, then the MOSFET is in blocking state, that is the resistance between the source and the drain pin is very high such that no current flows between those two pins. When applying a voltage above the threshold voltage of the MOSFET – since we are using logic-level MOSFETs, the threshold voltage should be below 5V – the MOSFET becomes conducting. The source and drain pins are now connected with each other and current can flow freely between those two pins.

Wiring

Let us start with the wiring of all components.

First of all, the ultrasonic transducer's signal and trigger pins are connected to pin 11 and 12 of the Arduino respectively. Certainly, the ultrasonic transducer is also connected to the power supply pins of the Arduino. The common cathode of each seven-segment display is connected via a 220Ω resistor to the particular MOSFET's drain pin. The MOSFET's source pins are connected with GND and the gate pins are connected with pin 9 and 10 of the Arduino. Whereby pin 9 belongs to the MOSFET driving the left display and pin 10 belongs to the MOSFET driving the right display. Further, each segment of both displays is connected to one of the pins 2 to 8.

Software

After successfully wiring all the components, the only thing missing is the software. Software for the Arduino is written in a dialect of C++ using the Arduino integrated development environment.

IDE

Besides, the main source code view the IDE provides a button to compile the source file and to upload it to the Arduino connected via USB with the computer.

Source-Code

We are already almost done! In the remainder of this tutorial, I will explain the source code which is necessary to display the measured distance in centimeters on the two displays.

First of all, we need to include the header file of the ultrasonic transducer library.

#include "Ultrasonic.h"

For convenience, we define readable names for the pin numbers using the pre-processor.

#define TRIGGER 12

#define ECHO 11

#define DISPLAY_A 8

#define DISPLAY_B 7

#define DISPLAY_C 6

#define DISPLAY_D 5

#define DISPLAY_E 4

#define DISPLAY_F 3

#define DISPLAY_G 2

#define DISPLAY_LEFT 9

#define DISPLAY_RIGHT 10

We further define an array which contains the pin numbers in alphabetical order of the segment letters they are connected to.

int ports[7] = {DISPLAY_A, DISPLAY_B, DISPLAY_C, DISPLAY_D,

DISPLAY_E, DISPLAY_F, DISPLAY_G};

To translate a digit to a specific pattern of enabled segments, we use yet another array.

int leds[10][7] = {{1, 1, 1, 1, 1, 1, 0},

{0, 1, 1, 0, 0, 0, 0},

{1, 1, 0, 1, 1, 0, 1},

{1, 1, 1, 1, 0, 0, 1},

{0, 1, 1, 0, 0, 1, 1},

{1, 0, 1, 1, 0, 1, 1},

{1, 0, 1, 1, 1, 1, 1},

{1, 1, 1, 0, 0, 0, 0},

{1, 1, 1, 1, 1, 1, 1},

{1, 1, 1, 1, 0, 1, 1}};

For example, the digit 0 is translated to {1, 1, 1, 1, 1, 1, 0} whereby each position states whether the corresponding segment of the display should be enabled or disabled. The function show(int x) displays the digit x on the display. Therefore it iterates over all segments, looks up the pin number of each segment and enables the segment depending on the corresponding pattern.

void show(int x) {

for (int i = 0; i < 7; i++) {

digitalWrite(ports[i], leds[x][i] ? HIGH : LOW);

}

}

What is still missing is the setup() function. The setup function sets the mode of all the pins we are using to OUTPUT and initializes the serial connection to the computer which is useful for debugging purposes.

void setup() {

for (int i = 0; i < 7; i++) {

pinMode(ports[i], OUTPUT);

}

pinMode(DISPLAY_LEFT, OUTPUT);

pinMode(DISPLAY_RIGHT, OUTPUT);

Serial.begin(9600);

}

Moreover, we need to initialize the ultrasonic transducer using the library.

Ultrasonic ultrasonic(TRIGGER, ECHO);

Finally, we need to write the loop() function. The loop function is executed in an infinite loop which consists of measuring the distance and then displaying it on the displays. To display the distance, we switch between the two displays using the MOSFETs with a rate of 10ms. We display the most significant digit of the distance on the left and the least significant digit on the right display. This way, both displays together show the distance measured in centimeters in the decimal system.

int select = 0;

void loop() {

int dist = ultrasonic.Ranging(CM);

Serial.println(dist);

for (int i = 0; i < 10; i++) {

if (select) {

digitalWrite(DISPLAY_LEFT, HIGH);

digitalWrite(DISPLAY_RIGHT, LOW);

show(dist / 10);

} else {

digitalWrite(DISPLAY_LEFT, LOW);

digitalWrite(DISPLAY_RIGHT, HIGH);

show(dist % 10);

}

select = !select;

delay(10);

}

}

Points of Interest

The summer school consisted of several groups. Every group leader had to give a plenum talk (in the evening). The topic for our group was "IoT - Today and Tomorrow", which was a mixture of common knowledge, interesting facts, and showing practical stuff.

In our presentation, we included a board using a ultrasonic transducer to showcase how a car distance sensor may be built. The live reporting of the distance was communicated to our presentation via WiFi, which was quite impressive for many people in the audience.

History

- v1.0.0 | Initial Release | 28.06.2018