SD Card Driver Development on COFILOS

Last year, I completed a major milestone for COFILOS and the Perseus board. I completed a fully TDD written SD Card Driver.

You may check the following video COFILOS SD Card.

It was a big pain to write it, even though I had guide code from the internet and enough relevant information. The outcome is a very readable and organized code.

The initialization phase is very complex (took the lion’s share of time to implement) and is shown here:

BOOL f_DriverSD_Start(void *pstDriver_ )

{

type_stDRIVERSD *pst_SD;

INT8U v_error;

INT8U v_PhysDevID;

BOOL v_retval;

pst_SD = (type_stDRIVERSD *) pstDriver_;

if (pst_SD->stDriver.eState != DRIVER_CLOSE) return 1;

if (pst_SD->f_HAL_HookCardPresent == NULL) return 1;

if (pst_SD->f_HAL_HookCardPresent() == 0) return 255;

v_retval = 1;

f_DriverSDHelper_InitSPI(pst_SD);

f_DriverCoFILOS_Open((PINT8) "SPI.Driver",

0xFF, (DRIVER_STRUCT *) &pst_SD->st_SPI);

Driver_Start((DRIVER_STRUCT *) &pst_SD->st_SPI);

Driver_Control((DRIVER_STRUCT *) &pst_SD->st_SPI, CMD_SET_SPIMUTEX_ON, NULL);

f_DriverSDHelper_ResetSD(pst_SD);

v_PhysDevID = pst_SD->v_PhyVolumeID;

st_SDPhysical[v_PhysDevID].v_UnknownCard = eSDUn_None;

pst_SD->v_CardType = eSDCardUnknown;

f_DriverSDHelper_SelectDevice(pst_SD);

v_error = f_DriverSDHelper_SendCMD0(pst_SD);

if (v_error == 0xFE)

{

f_DriverSDHelper_UnknownDevice(pst_SD->v_PhyVolumeID, eSDUn_CMD0);

}

else

{

v_error = f_DriverSDHelper_SendCMD8(pst_SD);

if (v_error == 0)

{

v_error = f_DriverSDHelper_SendACMD41(pst_SD, 0x40000000);

v_error = f_DriverSDHelper_SendCMD58(pst_SD);

if (pst_SD->v_CardType == eSDCardSDv2Byte)

{

v_error = f_DriverSDHelper_SendCMD16(pst_SD);

st_SDPhysical[v_PhysDevID].v_CardType = eSDCardSDv2Byte;

}

else

{

st_SDPhysical[v_PhysDevID].v_CardType = eSDCardSDv2Block;

}

}

else if (v_error == 0xFE)

{

st_SDPhysical[v_PhysDevID].v_CardType = eSDCardSDv1;

v_error = f_DriverSDHelper_SendACMD41(pst_SD, 0x00000000);

if (v_error != 0)

{

v_error = f_DriverSDHelper_SendCMD1(pst_SD);

if (v_error == 0)

{

st_SDPhysical[v_PhysDevID].v_CardType = eSDCardMMCv3;

}

else

{

f_DriverSDHelper_UnknownDevice(pst_SD->v_PhyVolumeID, eSDUn_CMD1);

}

}

if (v_error == 0)

{

v_error = f_DriverSDHelper_SendCMD16(pst_SD);

}

}

else

{

f_DriverSDHelper_UnknownDevice(pst_SD->v_PhyVolumeID, eSDUn_CMD8);

}

}

switch(st_SDPhysical[v_PhysDevID].v_CardType)

{

case eSDCardSDv1:

case eSDCardSDv2Block:

case eSDCardSDv2Byte:

f_DriverSDHelper_SendCMD9(pst_SD);

f_DriverSDHelper_SendCMD10(pst_SD);

break;

default:;

}

f_DriverSDHelper_DeSelectDevice(pst_SD);

Driver_Control((DRIVER_STRUCT *) &pst_SD->st_SPI, CMD_SET_SPIMUTEX_OFF, NULL);

if (st_SDPhysical[v_PhysDevID].v_CardType == eSDCardUnknown)

{

v_retval = 1;

}

else

{

st_SDPhysical[v_PhysDevID].v_DriverState = eSD_Started;

v_retval = 0;

pst_SD->st_SPI.v_ConfigReg = 0xA002;

}

st_SDPhysical[v_PhysDevID].v_OpenCnt = 0;

return v_retval;

}

After completing the TDD phase on my host (PC), I needed to run my tests on the actual target (ColdFire) microcontroller.

In the next picture, you may see the hardware setup along with my programmer. I used a micro-SD of 8GB from Kingston for test.

I had already captured the sectors (and image) of the SD card and saved them on my hard-drive. I wanted to be able to compare what the microcontroller would read with the actual data stored.

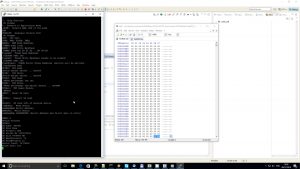

After having my target run the code, I opened a PuTTY terminal to connect with my virtual COM on my target. Then through the CLI (Command Line Interpreter) I mounted the SD card. I issued the SDInfo command and the data provided the SD card “geometry”.

I then read sector zero (or MBR for FAT file system). I compared the data with the image capture to confirm reading of the same piece of information.

The first FAT sector (0x2000) was also read and verified. I had to check it as I needed to run a FAT File System Handler to read the SD Card at a later stage (not very later, though).

Then, the write tests started. My write command in CLI supports a single 32-bit value write currently. This is sufficient at the moment to verify a sector write operation. So I used sector 1 which is unused to write the value 0x1234567.

Next, a read on sector 1 is performed to check that the sector was written. And voila! Notice the Big-Endian write (0x78 at byte 0, instead of 0x12).

At the same time during debugging, I used my Tektronix TDS3012B Digital Oscilloscope and a Python script to capture and decode the SD SPI data.

The script outputs also a VCD format file suitable for use with GTKWave. Thus, I could see and analyse the data, both analog and digital.

Due to the TDD methods used, the debugging phase on the target was very fast. With a few iterations and the help of the scope and the Python scripting tool, the SD card driver worked well.