Statement

The Internet of Things (IoT) is changing everything, including ourselves and our habits; just think about the impact the internet had in instruction, communication, economy, science and public administration fields, so clearly it’s about one of the most resounding inventions in history and for this, often we hear this referred to as the fourth industrial revolution.

IoT represents the next internet evolution, with an incredible improvement of collecting, analysing and distributing skills of convertible and/or converted data in information.

An object defined as IoT or Industrial Internet of Things (IIoT) is clearly an electronic product, but, differently from other ones that require more scientific skills for realizing the object scope. In the case of IoT, often, we assist to a real knowledge contamination among jobs apparently not related; just imagine making an industrial or semi-industrial machinery used everyday by a worker: twisting the machinery use probably will be necessary to effectuate more studies that will involve a more humanistic field.

The case

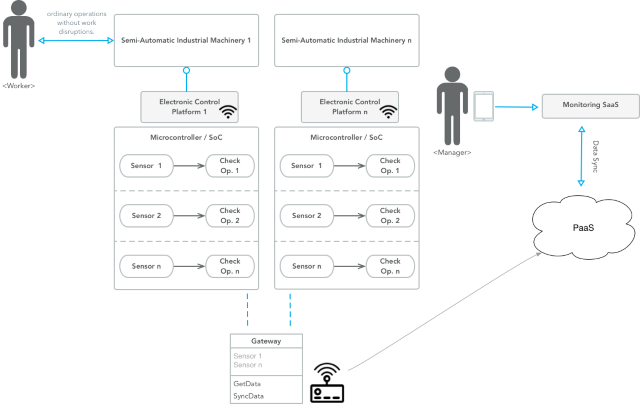

In this article we analyse the industry 4.0 possibilities and we will show how it is possible to make IIoT a semi-automatic machinery managed mainly by people.

Analysing the industry 4.0 trends we will see that, as for as it concerns the Italian market – mainly composed by little companies – the possible applications mainly concern the possibility to automate and control semi-automatic machinery and often not equipped with electronics with the purpose of controlling executed operations and so improving quality and production.

For the article purpose let’s take into consideration a semi-automatic machinery for food vessels filling; let’s look at some of the machinery functionalities so to understand how to control and monitor, for example: intake food, vacuum, and cap closure.

Clearly in this case the machinery is already equipped with its electronics for controlling the vacuum pump and closing the vessels, so to avoid affecting the existing electronics we can imagine connecting to operation executors’ buttons or levers so to record and check the worker did all the operations without forgetting anything for the vessels filling and also it would be possible to add lights to alert when the system notices not all operations have been done.

For example let’s give a look to this logical scheme

The machinery is so connected electronics such as a Genuino101* board with sensors and actuators (pressure sensor, buttons, LED, display), relieved and recorded data are sent to an Intel* NUC Gateway, the latter analyses and synchronizes data in Cloud with the purpose to make them available for other things (quality control check for example).

So, in this article I have only introduced the scenario, in the next, I will spoke how to develop it.